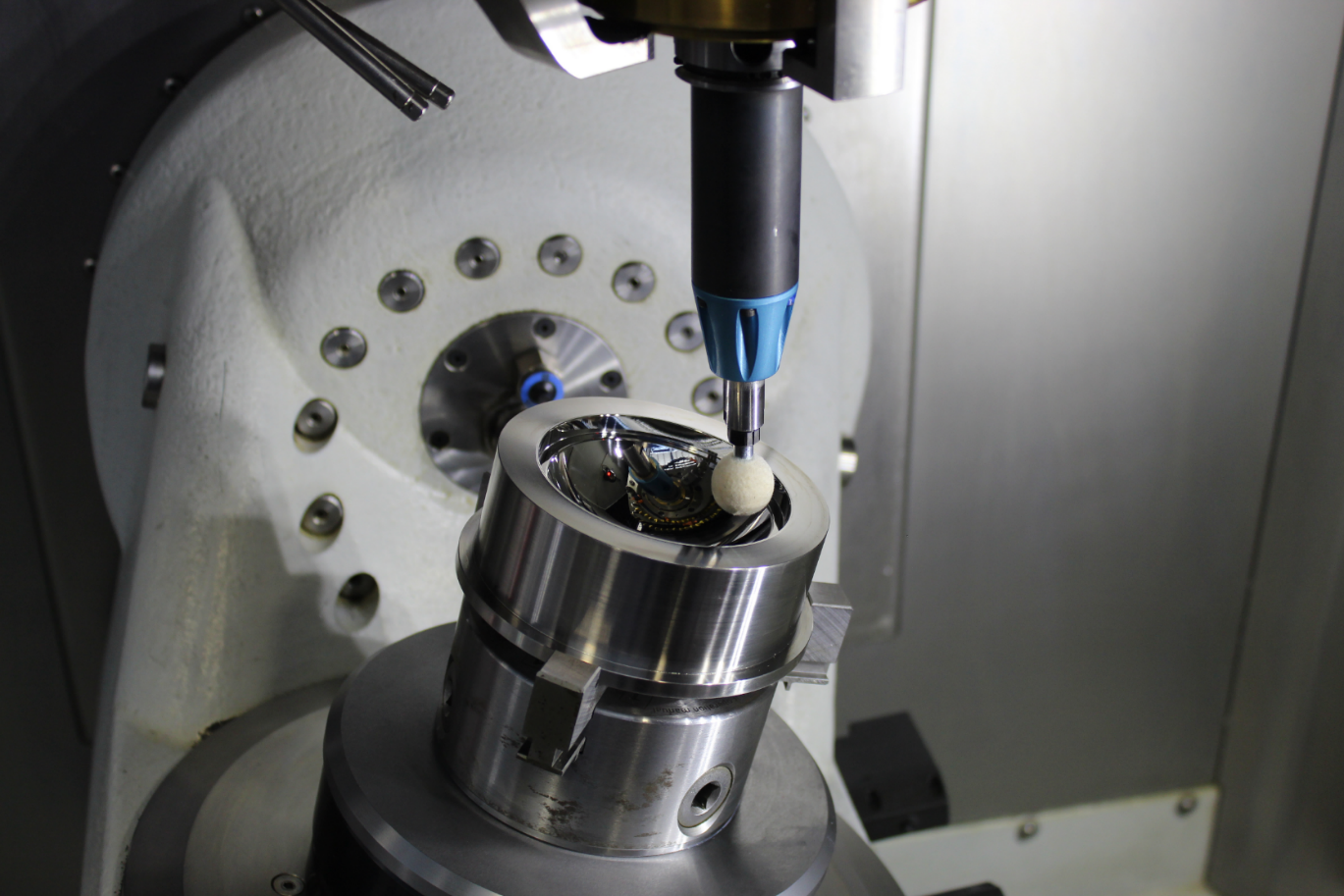

iCTS - The Intelligent Compliant Tooling System

Hi-automize offers the compliant tool holder iCTS for machine-integrated or robot-based automation of finishing processes, such as grinding, honing, lapping and polishing. The tooling system can be integrated into existing machine systems and processes without intense additional effort.

Our customers come from the automotive, turbomachinery, medical technology and further high precision manufacturing sectors!

Value

The tooling system iCTS is characterized by a sensitive bearing, which applies an adjustable, constant contact force to the component.

This enables the automation of fine machining processes. The iCTS system also automatically compensates for tool wear and referencing errors between tool and workpiece.

Success Story

SYMPLEXITY - A European Project for Finishing Automation

The iCTS was used as a key technology for automated finishing of complex surfaces with abrasive tools!